A feasibility study into using energy harvesting sensors to detect fires in cargo holds

13/05/2022This study details a collaboration between Safetytech Accelerator and Seaspan to explore the feasibility of using novel sensors to provide faster detection of container fires located below deck on ships.

The Challenge

Today, most container ships use fire detection systems that continuously draw air from below deck and direct it to a smoke detector. When smoke reaches the detector, an alarm is triggered and CO2 can be released to extinguish the fire. The downside of the current solution which has been in the industry for decades is that a significant amount of time passes before smoke actually reaches the detector and the fire will almost certainly have spread by this point.

Ships are continuously increasing in size and moving more & more containers every year. Existing technology is often inadequate to provide an effective and prompt fire detection in the cargo hold. On the other hand, seafarers have a significant task trying to extinguish fires with limited resources onboard. Each failed attempt presents a sizeable environmental, financial and, most importantly, human cost.

This study sought to virtually trial novel sensor solutions that could detect container fires faster than the current solutions with comparable deployment and maintenance costs.

The Solution

Safetytech Accelerator worked closely with Seaspan to outline the technology parameters for this challenge and source startups with novel sensor technologies. From the applications, three high quality startups were shortlisted to pitch their solutions to a panel of judges.

US-based Everactive was chosen to trial their energy harvesting temperature sensors. Their wireless sensors use a proprietary low-power network in combination with wired gateways. Power for the sensors is harvested from small amounts of light and/or temperature differentials, as well as other environmental sources. The battery-less wireless sensors were attractive to Seaspan because they could potentially fit into the 5 year maintenance schedules that are common in the shipping industry.

The Study

For obvious reasons we could not set fire to containers loaded on a ship. Instead the feasibility study used the services of Lloyd’s Register’s Computational Fluid Dynamics (CFD) team to simulate fires in a virtual environment.

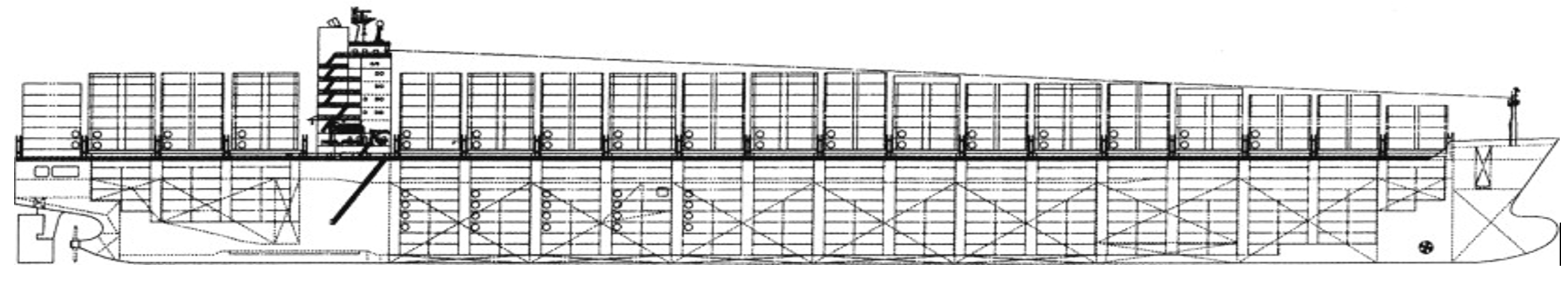

Everactive visited a typical container ship to learn about the conditions that temperature sensors would need to operate in. The learnings from that visit and the characteristics of the Everactive sensors were passed onto the LR CFD team to accurately simulate the performance of temperature detecting sensors. A representative cargo hold was simulated based on dimensions, container layout and ventilation information provided by Seaspan.

Typical causes of fires could be for various reasons; from mis-declaration, to International Maritime Dangerous Goods in-compatibility, inadequate packaging or pre-stuffing inspection & certification. As an example of mis-declaration, this study simulated a container holding undeclared charcoal which subsequently causes a fire.

The CFD simulations intended to answer the following questions

- How quickly can the sensors detect a fire?

- What are the optimal locations for sensor placement?

Three different fire scenarios were modelled

- Fire sealed in a container

- Fire breaching a container

- Fire in a leaking container

The Results

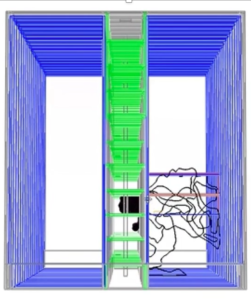

For the sealed container, the virtual temperature sensors detected a fire in 3:09 minutes before the fire self-extinguished due to lack of oxygen at 4:10mins. Traditional cargo hold smoke detectors would never have detected the fire as no smoke escaped the container. Heat was mostly contained in and immediately around the problem container suggesting that sensors should ideally be placed on the steel harnesses at the ends of the containers. Approximately 26 sensors were estimated to be required for each container wall. As there are 20 container walls, approximately 520 sensors would be required to provide coverage for an entire cargo hold on a typical ship.

When simulating container doors being breached by a fire (ie an explosion), all sensors in the hold quickly detected temperatures above 100°C. In this scenario the temperature sensors would not offer any advantage over the traditional smoke detectors in containing the fire.

A more realistic scenario was simulated where a container was not perfectly sealed, the temperature sensors detected a fire in 2:08 minutes as opposed to 10:15 minutes for a traditional smoke detector located in the exhaust vent stack. Typical cargo holds do not have a smoke detector at each vent stack intake.

Smoke detectors located at the hold’s exterior vents were never triggered as there was always enough air being drawn inwards to prohibit the flow of smoke (during a 28 minute simulation).

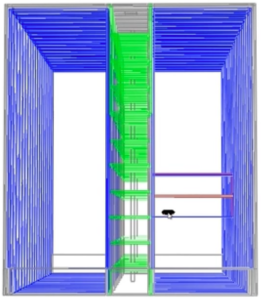

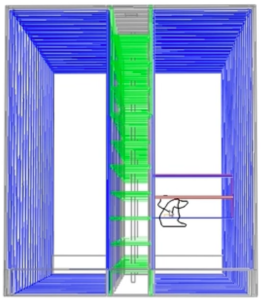

1.

2.

3.

Three stages of a simulated fire in a sealed container and how heat is dissipated around the hold

To summarise, the CFD simulation showed that temperature sensors could detect a fire approximately 26 minutes earlier than traditional smoke detectors.

Further trials onboard a physical ship are still required to validate the wireless communications in the dense steel structure below deck. The effort required to install wired gateways also requires further investigation since cables will need to be routed through the ship.

Industry-Wide Impact

A number of technology companies are now providing sensors that harvest energy from low-light, heat, vibrations, radio signals and electromagnetic induction. Over the next few years more industrial settings will be widely monitored using an array of low maintenance sensors, including container ships.

This feasibility study has shown that in theory there is an opportunity to detect container fires faster than the traditional detection solutions without the need to instrument each individual container within the cargo hold.

Early detection is key in mitigating the risk of fire outbreaks, and protecting assets, the environment and most importantly the lives of the crew.

>>>

About Seaspan

Seaspan, a wholly-owned subsidiary of Atlas Corp. (NYSE:ATCO) is a leading independent owner and operator of container ships. They charter their own vessels primarily to the world’s largest container shipping liners. As of March 2021, Seaspan’s fleet consisted of 127 containerships representing total capacity of just over one million TEU.

About Everactive

Everactive is a US based technology company that sells battery-less Internet of Things (IoT) solutions. They have developed always-on wireless sensors that are powered continuously and exclusively from energy harvested from the environment.

About Safetytech Accelerator

Safetytech Accelerator is a non-profit established by Lloyd’s Register. It is the first fully dedicated technology accelerator focused on safety and risk in industrial sectors. Our mission is to make the world safer and more sustainable through wider adoption of safetytech.