Case Study: Early Fire Detection on Container Ships using E-Nose Technology

04/10/2024Early Fire Detection on Container Ships using E–Nose Technology by SmartNanotubes in the Cargo Fire and Loss Innovation Initiative

CFLII Programme

Fires on container ships are becoming more frequent and severe, but current fire detection systems are outdated and slow to respond, risking lives and cargo. The Cargo Fire and Loss Innovation Initiative (CFLII), led by Safetytech Accelerator, addresses this issue by uniting maritime stakeholders to develop and implement faster, more advanced fire detection technologies. These efforts aim to exceed current safety standards and enhance global shipping safety. Current Anchor Partners of this initiative include Evergreen, ONE, Seaspan, Maersk, Offenship, UK P&I, TT Club, CMES, MSC, and Lloyd’s Register.

The Challenge

The Anchor Partners joined the Cargo Fire and Loss Innovation Initiative (CFLII) to tackle a critical challenge: the need for advanced technologies that can detect fires and other hazards at their earliest stages, well before conventional systems, which typically only activate after significant smoke or flames are present. The partners recognised that existing firefighting systems, based on outdated, reactive technologies, were insufficient for modern maritime safety needs. They sought a proactive solution capable of early detection of fires, as well as hazardous substances, such as fuel line breaks or dangerous cargo spills, particularly in unmanned machinery spaces and cargo stowage areas.

Solution: E-nose Technology

Safetytech Accelerator worked with the Anchor Partners to identify, refine, and translate their requirements into a challenge brief. This brief was then used to scan the market and source a groundbreaking organisation innovating in cutting-edge e-nose technology. SmartNanotubes Technologies (SNT) and Duotec’s system use chips embedded with carbon nanotubes that continuously sample air molecules and recognise the unique chemical signatures, or “fingerprints”, of specific smells associated with operational processes or hazardous materials.

This technology was identified as having the potential for much earlier alarm activation than traditional systems in the maritime market due to its success in other sectors such as healthcare and air quality detection. Therefore, it was necessary to test SNT’s e-nose sensor in collaboration with Anchor Partners to refine the innovation for real-world maritime conditions, ensuring it meets the stringent requirements of ship owners and integrates effectively into maritime safety protocols.

Testing it with Anchor Partners

Safetytech Accelerator, in partnership with SmartNanotubes and other Anchor Partners, conducted a two-phase pilot to validate the e-nose technology in the maritime sector.

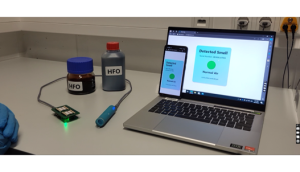

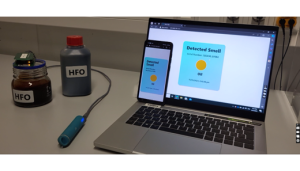

Phase 1: Laboratory Testing

The initial lab tests in Freiberg, Germany, compared the e-nose with standard smoke detectors and temperature sensors. The e-nose quickly detected smells from heating charcoal and heavy fuel oil (HFO) within five minutes, while traditional sensors failed to respond during the test.

Phase 2: On-Vessel Testing

The technology was then installed on Offenship’s MSC Vigo container ship. The e-nose operated reliably in the maritime environment, detecting wood fire and HFO spill smells within 2–5 minutes. It also distinguished hazardous smells from normal operations, proving effective in real-time hazard detection.

Results

The results of these tests demonstrate several key capabilities of the e-nose sensors:

- Continuous and reliable operation in the maritime environment without degradation or impact from vibrations.

- Detection of wood fire and HFO spill smells within 2–5 minutes, even without smoke.

- Ability to distinguish between hazardous smells and normal operational smells by unique signal patterns.

- Effective monitoring of normal operations and detection of smell anomalies, indicating potential hazards.

“Imagine you could smell, with high accuracy, the specific odour of a Li-ion accumulator starting to heat up during the process of a thermal runaway, potentially resulting in a serious fire. Or imagine smelling fuel oil in the atmosphere of a ship’s engine room after a small crack in a high-pressure fuel pipe starts to spray fine droplets of a serious fire hazard into the air. Sounds futuristic?

Well-conducted trials we did with SmartNanotubes and duotec have proven that both scenarios are already within the reach of this relatively new technology. It doesn’t take much imagination to conclude that the number of use cases is only limited by the database being collected and the evolution of the software and AI screening for certain incidents. So, the e-nose will remain open to any new smells.”

— Capt. Ortwin Muehr, Head of Nautical Department, Offenship

Impact on the Maritime Sector

According to the DBI, the number of fires on container ships has doubled over the past twenty years. Introducing e-nose technology in maritime safety represents a significant advancement in early fire detection and hazard monitoring. Unlike traditional smoke detectors and temperature sensors, e-nose sensors can detect hazardous conditions much earlier, providing crucial time for preventive measures.

Should this type of early fire detection technology be widely adopted, the impact for shipping companies could be substantial, including cost avoidance in case of accidents, improved safety for crew and the environment, and reduced compliance and insurance costs.

The CFLII programme, its Anchor Partners, SNT, and duotec will continue refining and validating the technology over the coming months.

To find out more about the Cargo Fire and Loss Initiative, e-noses, and SmartNanotubes, get in touch here.

END

About CFLII

The Cargo Fire & Loss Innovation Initiative (CFLII), launched in February 2023 by Safetytech Accelerator, unites industry leaders, technology innovators, and maritime stakeholders to advance technologies that prevent and mitigate large-scale cargo fire, loss, and damage at sea. With a focus on enhancing shipping’s reputation as a safe, reliable, efficient, and environmentally responsible link in the global supply chain, CFLII includes leading shipping companies, representing around 50% of the global container capacity, and maritime insurers as its Anchor Partners.

CFLII Full list of Anchor Partners: Evergreen, Lloyds Register, Maersk, Ocean Network Express, Offen Group, Seaspan Corporation, TT-Club and UKP&I.

About Safetytech Accelerator

Safetytech Accelerator, established by Lloyd’s Register, is the first fully dedicated technology accelerator focused on advancing innovation in safety critical industries. Our mission is to make the world safer, more resilient, and more sustainable through the wider adoption of technology.

About SmartNanotubes Technologies GmbH

SmartNanotubes Technologies was founded, after 10 years of research on nanomaterials, in 2020 by Dr. Viktor Bezugly and Dr. Birte Sönnichsen. SmartNanotubes’ sensors can detect single gases, smells and volatile organic compounds (VOCs). Applications range from environmental and security applications to home and industrial safety, wearables and IoT lifestyle products. The multi-channel sensor module can be easily integrated into various devices.

About duotec GmbH

duotec is a globally operating electronics service provider. duotec has invested for years in innovative manufacturing technologies as well as in basic research and the development of state-of-the-art microelectronics. duotec uses its existing know-how to think out of the box with the aim of pushing innovations and always being a little ahead of the competition. This claim is expressed in the new slogan” Ahead of Innovation”. For more information, please visit: www.duotec.net